Just how do inkjet printers work?

Inkjet printers are a familiar picture in homes and offices, used to print research, updates and photographs for family or estimates, invoices, types and colour business documents for small enterprises. But perhaps you have stopped to take into account how they work? Inkjet printers have actually functioned in around the same way since HP launched its initial ThinkJet printer in 1984, but this might be switching – and these modifications are revolutionising publishing.

Just how can traditional inkjets work?

In a conventional thermal inkjet printer, ink is given directly into several thousand small reservoirs when you look at the printhead from cartridge, then heated rapidly by a tiny resistor, which causes the ink to create a bubble. This bubble after that propels the miniscule droplets through a nozzle on to the web page, in which each forms an equally miniscule dot. These dots form the outlines, characters and discreet gradations of colour we see in a finished printout, whether that’s a simple letter, a 20-page report full of charts and graphs or a family picture.

In black-and-white images, spots of black colored ink, put specifically in microscopically managed volumes, create crisp, black text and smooth lines. In full-colour images, colored spots of to eight different colored inks tend to be layered precisely in habits or on top of 1 another, producing the impression there are millions of various colours regarding page.

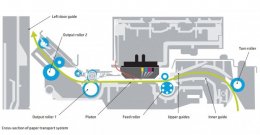

It’s smart things, although traditional inkjet has its own restrictions. The printhead is extremely small and will just deposit ink on a little section of the paper at the same time, which means that the printhead has to travel straight to left then left to correct throughout the sheet, printing one line of dots at a time. once the range is finished, the report transport process – the process that pulls report in the printer, under the printhead as well as in towards production tray – moves the report into place for the second range.

once the range is finished, the report transport process – the process that pulls report in the printer, under the printhead as well as in towards production tray – moves the report into place for the second range.

This restrictions printing rates, considering that the printer has to wait for the printhead which will make its means throughout the page prior to the report transportation apparatus can perform its stuff. Additionally influence lasting dependability, given that printhead’s horizontal motion means another mechanism that’s subject to wear and tear. It may also impact quality, once the motion for the printhead helps it be harder to lay-down all those dots with such accuracy.

Inkjet printers have improved considerably over the past 30 years. They’ve gone from rates of 2 pages each minute (ppm) to a lot more than 30ppm, while resolutions have actually leapt from 300 dots per inch (dpi) to 2, 400dpi. However, the restrictions of the printhead are actually holding the inkjet back. They stop it from printing quicker and dealing with the sort of workloads you’d expect from a laser printer.